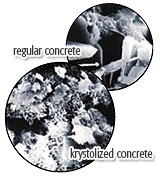

Microscopic, needle-like crystals fill the naturally occurring pores and capillary tracts of concrete for guaranteed waterproof structures.

Krystol® Concrete Waterproofing technology is based on principles that are very similar to the processes that occur during the hydration and hardening of concrete. Cement is mainly made up of several calcium silicates. When cement particles are mixed with water, a chemical reaction occurs whereby these calcium silicates combine with the water to form new compounds. The new compounds are calcium silicate hydrate (CSH) and calcium hydroxide.

The CSH forms as an amorphous microcrystalline structure, extending outward from the individual cement particles and eventually filling the space between them. The CSH crystal formation is the mechanism by which the concrete stiffens and gains strength. It is most dramatic in the first hours after the concrete is placed, but actually continues for weeks, months and even years into the life of the concrete.

The reason that hydration can continue, seemingly indefinitely, is because only a portion of the cement has reacted during the initial hydration and hardening of the concrete. A significant portion of each cement particle remains un-reacted long after the concrete has reached its design strength. It is the un-reacted particles that allow the Krystol chemicals to perform their function. Krystol acts as a catalyst to a larger reaction within the concrete mass.

This is significantly different from silicate-based products that react with compounds in the concrete such as calcium hydroxide or free lime. The reaction binds such a treatment into an insoluble solid and hopefully blocks the pores. These products quickly become completely bound in place and therefore do not penetrate more than a few millimeters into the concrete. For the same reason, these products will not reactivate to self-seal new cracks that may form. In fact, they are insoluble and the presence of water in the future has no effect on them.

Krystol, on the other hand, works quite differently. The crystals that are formed are hydration crystals, but they are not amorphous like cement hydration crystals. Instead, they form into a crystalline structure of long hexagonal prisms that extend through and fill the capillary voids and micro-cracks of the concrete. The crystals themselves are not made up solely of the Krystol material, but grow from the partially reacted cement particles. This is why the crystals can travel many inches through the concrete.

When added or applied to concrete, crystalline chemicals create a reaction that causes long, narrow crystals to form, filling the pores, capillaries and hairline cracks of the concrete mass. As long as moisture remains present, crystals continue to grow throughout the concrete, reaching lengths of many inches over time. Once the concrete has cured, the crystalline chemicals sit dormant until another dose of water (such as through a new crack) causes the chemical reaction to begin again.

The ability to reactivate in the presence of water gives crystalline-treated concrete the ability to “self-seal”. When cracks form due to curing shrinkage, settling, seismic activity, etc., water entering through them causes new crystals to form and grow, blocking and filling the cracks. Its ability to self-seal cracks is one of crystalline technology’s most unique and useful features, and can help to dramatically reduce the long-term maintenance and repair costs of a concrete structure.

SMART CONCRETE®

SMART CONCRETE®